How to Maintain a Drill Machine: A Complete Guide

Think of your drill machine like a trusted pickup truck. You rely on it to start every time, to have the power to haul a heavy load, and to get you where you need to go. But you wouldn’t just drive that truck for years without ever changing the oil or checking the tire pressure, would you? Of course not. Your drill, the workhorse of your tool collection, deserves that same level of care.

Proper maintenance is the single most important factor in a power tool’s lifespan and performance. It’s the difference between a drill that dies a premature death, sputtering and sparking, and one that serves you faithfully for decades. A few minutes of simple, regular care can save you hundreds of dollars in replacement costs and ensure your drill delivers peak power and precision every time you pull the trigger.

This is your complete owner’s manual for drill care. We’ll walk you through a simple, actionable maintenance checklist—from the 2-minute routine you should do after every use to the deep-cleaning tasks that will keep your tool running like new. Let’s protect your investment.

The Payoff: Why Bother with Drill Maintenance?

Before we get into the “how,” let’s quickly cover the “why.” Understanding the benefits will motivate you to build these simple habits.

- Drastically Increased Lifespan: Dust and debris are the enemies of an electric motor. Regular cleaning prevents the buildup that causes parts to wear out and fail. A well-maintained drill can easily outlast a neglected one by years.

- Peak Performance: A clean drill is a cool drill. When air vents are clear, the motor can cool itself effectively, allowing it to run at its optimal power level without bogging down. Clean battery contacts ensure a solid electrical connection for maximum power transfer.

- Enhanced Safety: A dirty, gritty chuck can fail to grip a bit securely, causing it to slip or even fly out during use. A frayed cord is a serious electrical hazard. Maintenance is safety.

- Long-Term Cost Savings: The math is simple. Spending a few dollars on compressed air and lubricant is infinitely cheaper than spending a few hundred on a new professional-grade drill.

The Drill Maintenance Checklist: A Routine for Peak Performance

The best way to approach drill maintenance is to break it down into a simple, repeatable routine. We’ve organized it by frequency, from the quick tasks you should do every time to less frequent deep-cleaning procedures.

After Every Single Use: The 2-Minute Drill Down

This is the most important routine. Five minutes of work after a project will prevent 90% of common drill problems. Think of it as washing your hands after getting them dirty.

Step 1: Wipe Down the Housing

Use a dry cloth, a soft brush, or a microfiber towel to wipe away all the sawdust, drywall dust, and other debris from the drill’s plastic body. This prevents the grime from getting caked on and working its way into the tool’s seams and vents.

Step 2: Blow Out the Vents (CRITICAL STEP)

This is the absolute number one maintenance task you can perform. Your drill’s motor generates a lot of heat, and the air vents on the housing are its cooling system. When these get clogged with dust, heat gets trapped, and the motor will quickly overheat, leading to permanent damage.

Using a can of compressed air or an air compressor with a nozzle, blow short, powerful bursts of air through all the vents. You’ll be amazed at how much fine dust comes out. Make this a non-negotiable habit.

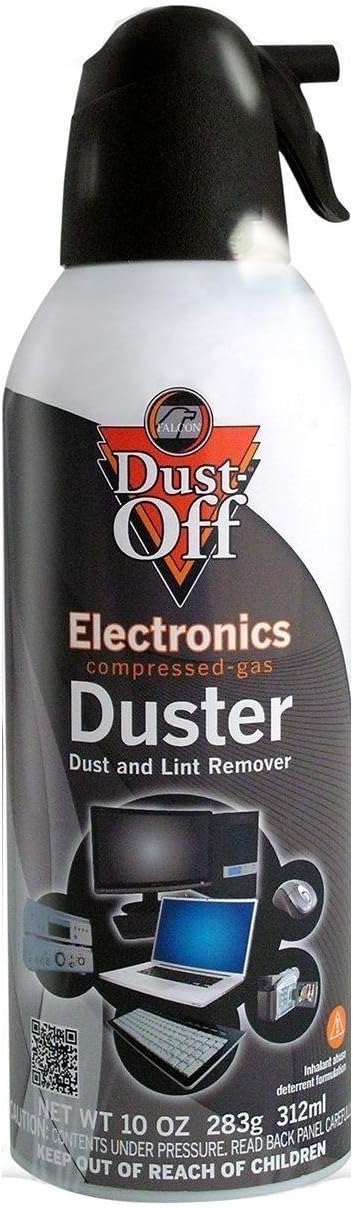

Maintenance Essential: Compressed Air Duster

This is the most useful tool for power tool maintenance, period. A can of compressed air is perfect for blasting dust out of motor vents, chucks, and tight crevices where a cloth can’t reach. It’s inexpensive, effective, and safe for electronics. Keeping a can on your workbench is one of the smartest things you can do for your tools.

Primary Use: Cleaning motor vents and electronics

Pro Tip: Use short bursts and hold the can upright to prevent the liquid propellant from spraying.

Step 3: Inspect the Power Cord

For corded drills, quickly run your hand and eyes along the length of the power cord. You’re looking for any nicks, cuts, exposed wires, or damage near the plug. A damaged cord is a safety hazard and should be repaired or replaced immediately.

Monthly Maintenance: The Deep Clean & Tune-Up

Once a month, or after a particularly heavy project, take 15-20 minutes to give your drill a more thorough check-up.

Step 1: Deep Clean the Housing

For stubborn grease or grime, use a cloth lightly dampened with a mild all-purpose cleaner or degreaser. IMPORTANT: Always remove the battery or unplug the drill first. The cloth should be damp, never wet, and you should avoid getting any liquid near the motor vents or switches.

Step 2: Clean and Lubricate the Chuck

A gritty chuck can be hard to tighten and may not grip bits properly. Open the chuck jaws all the way. Use a toothbrush or a small nylon brush to scrub out any debris from inside the jaws. Follow up with a blast of compressed air.

Next, apply a dry lubricant. Regular oil-based lubricants like WD-40 can attract sawdust and turn into a sticky mess. A PTFE-based dry lube spray is the perfect solution. Give a single, quick spray into the seams of the chuck mechanism, then open and close the jaws a few times to work it in. This will keep the action smooth and prevent rust.

Maintenance Essential: 3-IN-ONE Dry Lube

Unlike wet lubricants, this PTFE-based formula creates a long-lasting, slick surface that doesn’t attract dust, dirt, or oil. This makes it the ideal choice for lubricating sensitive mechanisms like a drill’s keyless chuck, saw blade pivots, and other moving parts that need to stay clean. A quick spray keeps everything moving smoothly without creating a gummy residue.

Primary Use: Lubricating chucks, moving parts

Benefit: Does not attract dust and debris.

Step 3: Care for Battery Contacts

For cordless drills, the connection between the battery and the tool is vital. Over time, these metal contacts can get dirty or even corrode slightly, leading to poor performance. Inspect the contacts on both the battery and inside the drill’s handle. If they look dull or dirty, gently clean them with a pencil eraser or a cotton swab dipped in isopropyl alcohol. This ensures a clean, efficient flow of power.

Long-Term Care: Storage and Battery Health

How you store your drill and its batteries between projects is just as important as cleaning it.

Proper Storage is Key

Store your drill in a cool, dry place. The worst places for a drill are the back of a hot truck in the summer or a damp, unheated shed in the winter. Extreme temperatures are murder on Li-ion batteries and can cause internal components to degrade. The hard case that came with your drill is your best friend—it protects from impacts, moisture, and dust.

Master Your Battery Strategy

Lithium-ion batteries have revolutionized cordless tools, but they have specific needs:

- Avoid Deep Discharges: Don’t run your battery until it’s completely dead. This strains the cells. It’s best to recharge it when you feel the power starting to drop off (around 20-25% capacity).

- Heat is the Enemy: Never leave your batteries in a hot car or in direct sunlight. Heat is the number one killer of battery lifespan.

- Long-Term Storage: If you’re not going to use a battery for a few months, don’t store it fully charged or fully empty. The ideal storage state is around a 40-50% charge.

Start with the Right Tool

Of course, maintenance is easier when you start with a quality, well-built tool. A cheap, poorly designed drill will fail no matter how well you care for it. If you’re in the market for a new tool that’s built to last, our comprehensive guide on choosing the right drill machine is the perfect place to start. And if you’ve already decided between power sources, check out our top picks for the best cordless drills and the best corded drill.

Troubleshooting Common Drill Problems

If you follow the steps above, you’ll avoid most issues. But if problems do arise, here’s a quick guide.

| Problem | Likely Cause & Solution |

|---|---|

| Drill is overheating or smells hot | The motor vents are almost certainly clogged. Unplug/remove the battery and thoroughly clean the vents with compressed air. Let it cool completely before use. |

| Chuck is stuck or hard to turn | Debris is likely jammed in the mechanism. Clean it out with a brush and compressed air, then apply a dry lubricant. |

| Cordless drill seems weak or dies quickly | First, ensure the battery is fully charged. Second, clean the battery and tool contacts. If the problem persists, the battery may be reaching the end of its life. |

| Excessive sparks from the motor vents | A few small sparks are normal in brushed motors. A shower of large, bright sparks means the carbon motor brushes are likely worn and need to be replaced. |

Frequently Asked Questions

How do you lubricate a drill chuck?

The best way is to use a PTFE-based dry lubricant spray. Wet oils attract dust and create a sticky mess. Open the chuck jaws, give a quick spray into the internal mechanism, and then work the chuck open and closed a few times to distribute the lube.

How can I make my cordless drill battery last longer?

The three golden rules are: 1) Avoid running it completely dead, 2) Keep it out of extreme heat, and 3) For long-term storage, leave it at a partial charge (around 50%) rather than full or empty.

Why is my drill sparking so much?

If you have a brushed motor, a small amount of sparking where the brushes contact the commutator is normal. However, if you see a sudden increase in sparking, or large, bright sparks, it’s a sign that the carbon brushes are worn down and need to be replaced.

Is it okay to leave a drill battery on the charger?

Modern “smart” chargers are designed to stop charging once the battery is full, so leaving it on overnight is generally safe. However, for the absolute best long-term battery health, it’s best practice to remove the battery from the charger once it’s full. Never store the battery on the charger for days or weeks at a time.

Conclusion: A Tool for Life

Your drill is an investment in your capability to build, create, and repair. Like any good investment, it requires a little upkeep to provide the best returns. By incorporating these simple cleaning, inspection, and storage habits into your workflow, you’re not just maintaining a tool—you’re cultivating a habit of craftsmanship and respect for the equipment that helps you get the job done.

Treat your drill well, and it will reward you with years of reliable, powerful service. And remember, proper use of a drill machine is the first and most important step in its long-term care.